Why MegaWindForce

Wind energy is developing towards one of the most important energy sources and plays a major role in realising the targets of the Paris Climate Agreement.

How fast the wind blows, how often, and when – all play a significant role in the power generation cost of the wind turbine.

MegaWindForce turbines bring down the cost of wind energy:

increasing the efficiency of the wind turbines

developing new technology in performance, applied materials and production techniques

optimizing the manufacturing and maintenance process of wind turbines

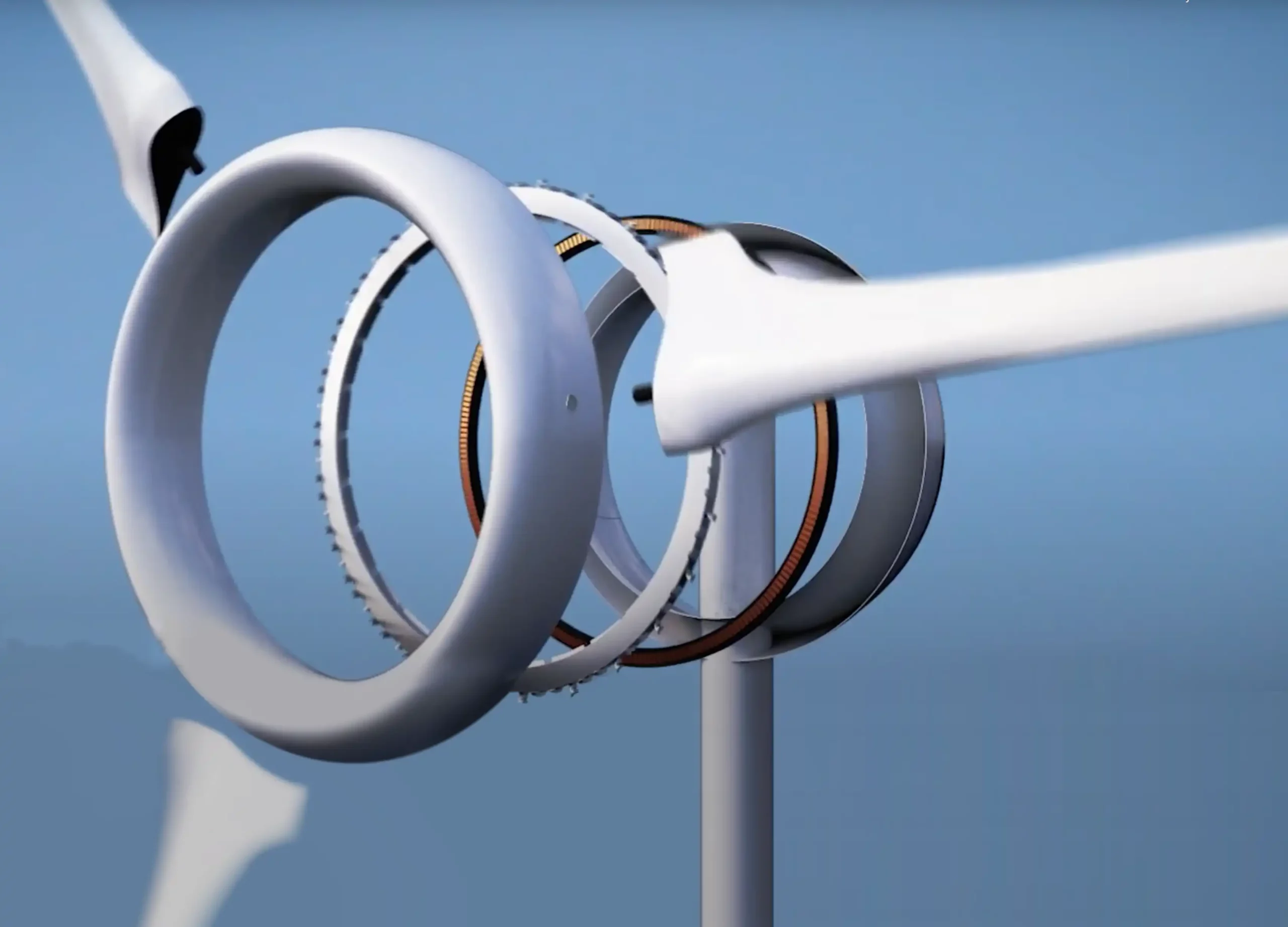

The MegaWindforce patented ring shaped generator and full carbon design will create a highly efficient wind turbine with a lower Cost Of Wind Energy (LCOE). The design is combining the proven techniques from aerospace, electrical and mechanical engineering; introducing the first-ever wind turbine that has no hub, no nacelle and no gearbox whilst maximizing capacity, any where the wind blows

MegaWindForce turbines designed to become the next wind energy standard

up to 80% weight reduction

20% to 40% LCOE reduction

competitive to fossil energy

The MWF turbine has no central shaft. Instead, there is a moving rotor in the ring, significantly lowering the stresses on critical positions. The reduced weight of the construction optimises the effectiveness of the turbine. The design eliminates the costly gearbox and the inefficient direct drives in the drive train. The turbine is made of Carbon Fibre Reinforced Plastics (CFRP), a composite material made of carbon fibres and thermoset resin. The use of CFRP adds strength where needed and eliminates weight where possible. MWF carbon elements are produced automatically, using the raw carbon materials and the conventional huge moulds are therefore not necessary. The result is a corrosion free turbine, weighing less than traditional turbines and with overall lower maintenance cost. The ring contains the elements to generate electricity and due to the high path velocity of the moving generator parts in the ring, AC current at a high frequency is created.

“…in a nutshell, it appears that MegaWindForce have identified a combination of technologies that can together enable new levels of performance…”

Key facts

LCOE can drop below fossil cost in wind-rich areas

The ring generator divided in many separate modules can be adjusted ON/OFF depending on the actual wind speed.

The design life time is 30 years with technologies proven outside the wind industry

Low and easy maintenance due to Carbon Fiber Reinforced Composite construction

Low noise (tip speed 59 m/s < 70 dB(A), whilest current industry standard is at 85 m/s, > 100 dB(A)

80+ % weight reduction due to the ring generator and used materials

Minimum use of rare-earth elements (only 70 kg of Neodymium required in 2m ring generator)

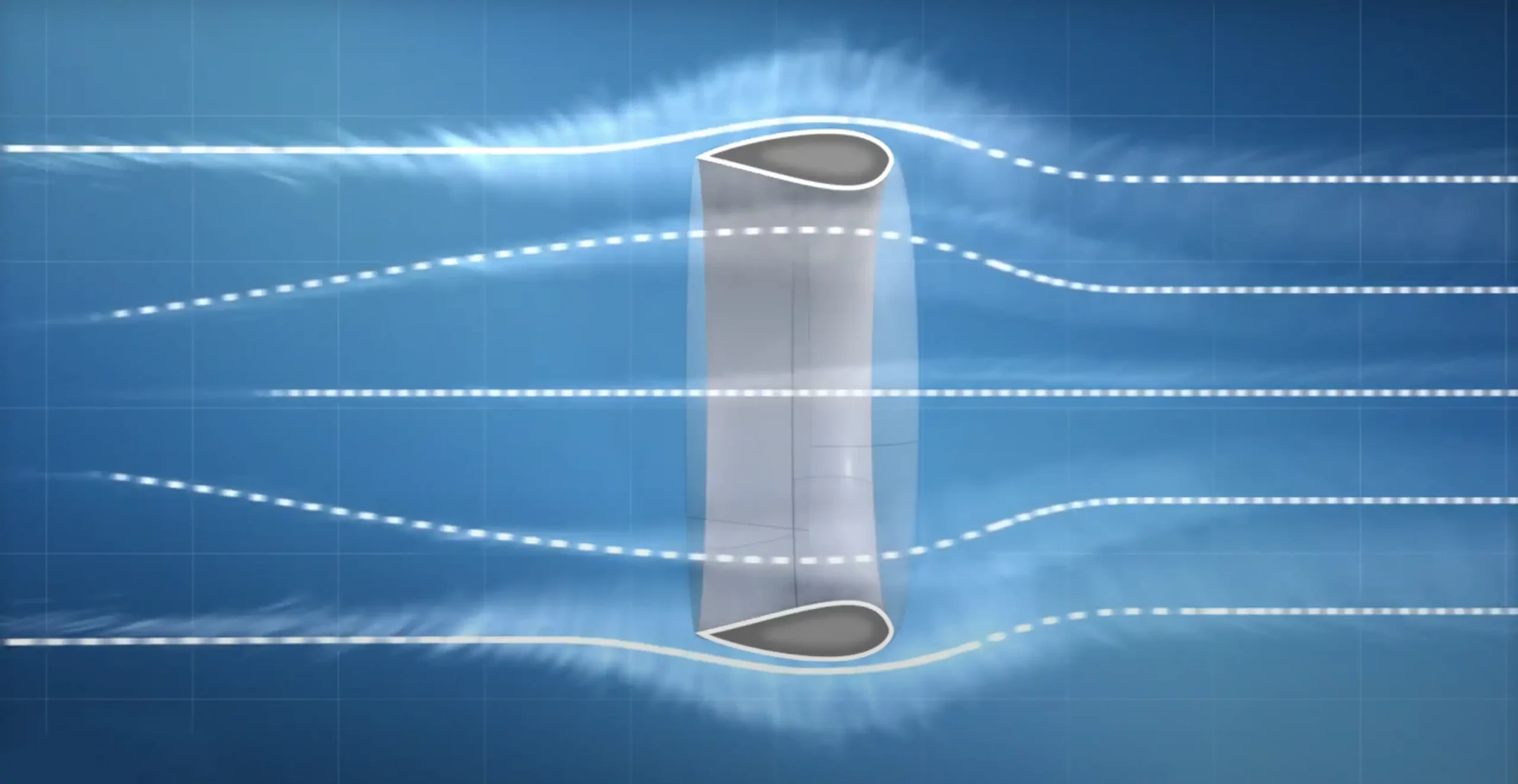

Reduced wake effect - more wind turbines per km2

Patented globally

Lets get in touch

MegaWindForce

Veldzigt 2A

3454 PW, De Meern

THE NETHERLANDS